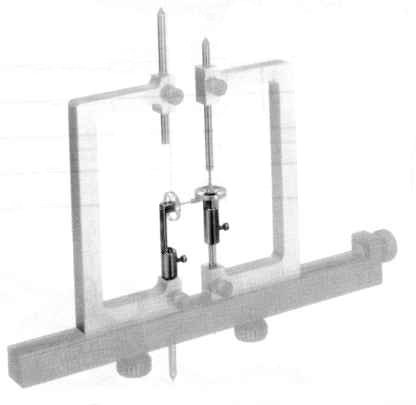

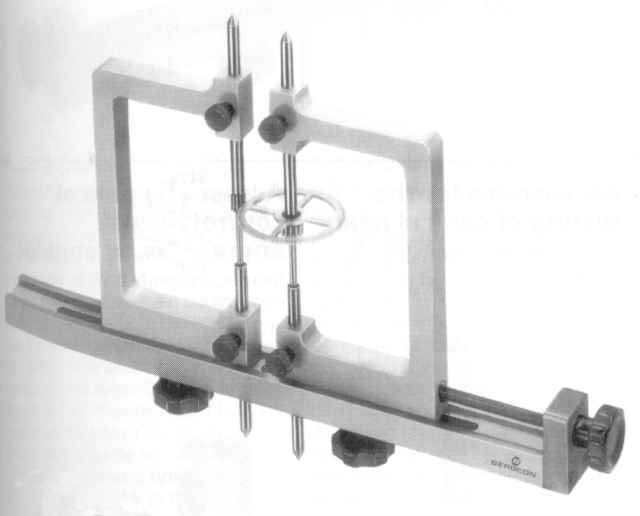

Once wheels are made, it is important to check their correct mesh. For this purpose, a depthing tool is used. Our model is a Swiss Bergeon of new design.

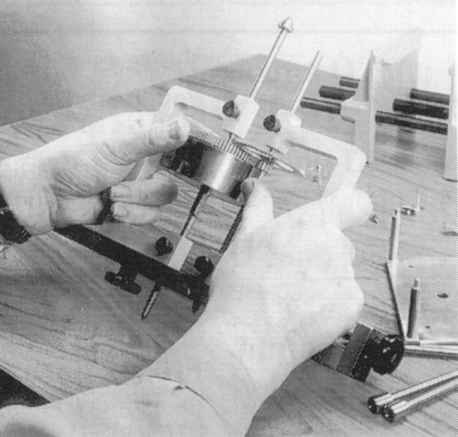

Shown here during the meshing test between a barrel wheel and its pinion.

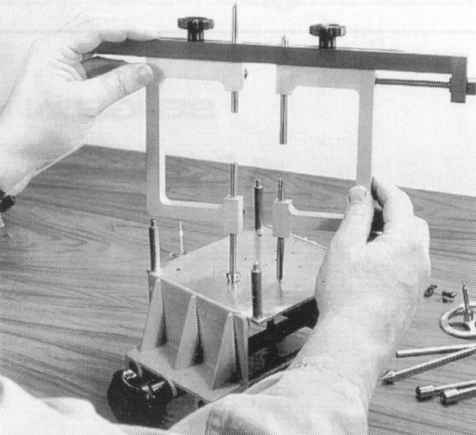

The distance between two pivot holes on a clock plate is measured.

Furthermore, by the use of two simple accessories conical gears can be tested too. These are typically found on verge clocks.