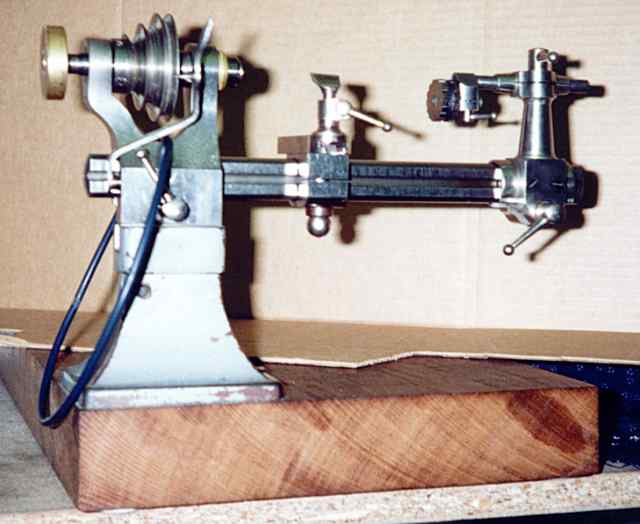

h and clockmaker's tools must, first of all, follow high quality standards. For this reason they are often very expensive. Sometimes they are used in a particular manner and require to be individually modified. Antique tools are often still in use. Our workshop follows this tradition: this 6 mm. Lorch lathe (built at the beginning of this century) is used daily for light drilling and finishing tasks. With this lathe balance staffs are made for those calibers whose spare parts are no more available, starting from simple steel bar. By the way, an interesting CD-ROM with plenty of references to watch parts can be obtained by Chris Heal.

It has to be remembered anyway that a modern electronically controlled Bergeon 6800 motor powers it (left).

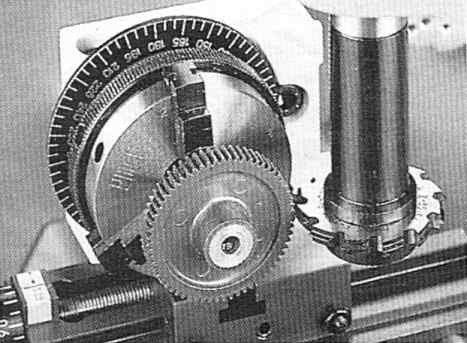

On the right, the three dogs mandrel, used for off-centre cuts on odd shaped parts. Fixing a plate on it, for example, allows cutting a recess for a wheel in any position by a tool mounted on a cross slide rest.

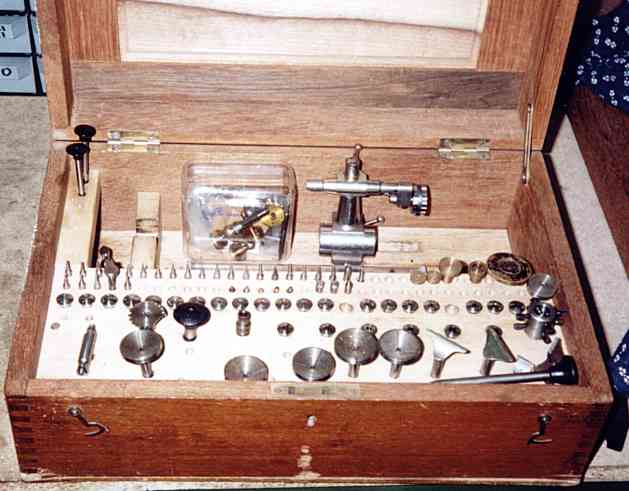

Below you can see a number of its accessories in the typical wooden box.

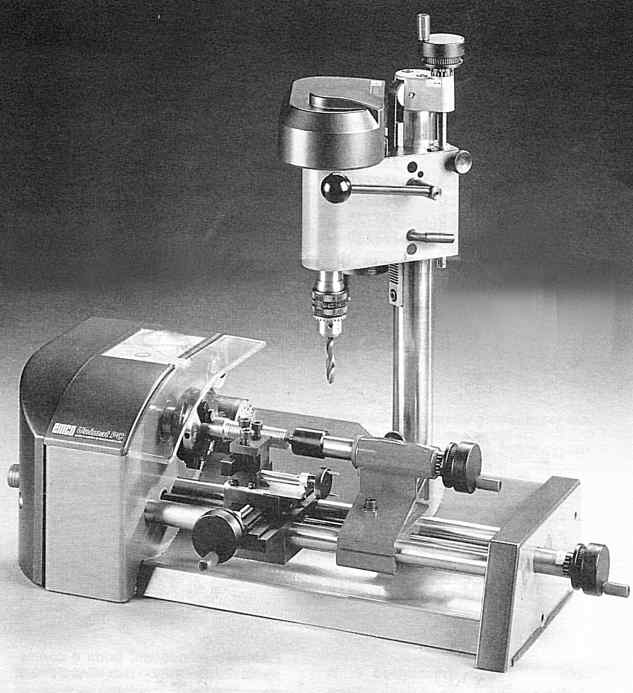

For heavier turning or milling tasks, larger lathes are employed, like this Emco Unimat PC.

In the picture below, you can see the lathe making a thread.The vertical milling and drilling attachment is mounted, too. We could cut left threads after a modification to change gears.

With this machine, a complete pendulum clock can be made, even if of relatively simple design.

It is capable of creating a wheel starting from simple brass plate or stock thanks to a system of dividers and milling column. The only limit being it cannot cut wheels with a large number of teeth using standard equipment.