When reading August issue of the Journal, we noted that Eric Gent gave the recipe for his clock cleaning solution. It is ammonia based and immediately we expected a lot of complains from our fellow clockmakers. We suspect that the Editor has already received many of them.

This is a very long debated problem: it happens to speak about it with other repairers and restorers more often than any other horological matter. Cleaning solutions appear to be a crucial point in our job. But is it really so?

We are all aware of damage that ammonia causes to brass. In our workshop, ammonia based cleaning fluids are not used for cleaning clock parts. We adopt an ultrasonic tank for the purpose, but this is mostly due to practical reasons. It appears to be much more time saving to wash parts in ultrasonic tank with special soap and water than immersing them in a container filled with ammoniated fluid. This have to be put apart after cleaning, smells bad, produces froth and must be very carefully rinsed. The only advantage towards the ultrasonic method is that the oxide on brass is to some extent removed, but this is far from being enough on a restoration job, where parts must be polished to a shine finish, and is of no importance at all in a conservative job.

Nevertheless, we do not condemn those colleagues using ammonia, and we will try to explain why.

We use ammoniated fluids for watches in an automatic washing machine where movements, both mounted and dismantled, pass through a preliminary bath (8 minutes), an ultrasonic bath (8 minutes), three rinsing baths made with benzene (8 minutes each) and a drying system with hot hair (8 minutes). This method has stood the test of many years of use and in no occasion a single watch showed problems due to residual dirt.

Movements are kept in a rotating container which, when not poised, causes noisy vibrations. To avoid them, we counterpoise the container with old alarm clock barrels or scrap watch movements. This is the list of the “counterweights” we have used:

1) - two Peter alarm clock barrels, brass; used for 11 years; ca. 600 washes each;

2) - one mechanical vintage wristwatch movement, nickel plated; used for 5 years; ca. 150 washes;

3) - one mechanical modern wristwatch movement, nickel plated; used for 5 years; ca. 150 washes;

4) - one quartz wrist movement plate, nickel plated; used for 4 years; ca. 100 washes;

5) - one mechanical modern wristwatch movement, gilded; 2 years; ca. 50 washes.

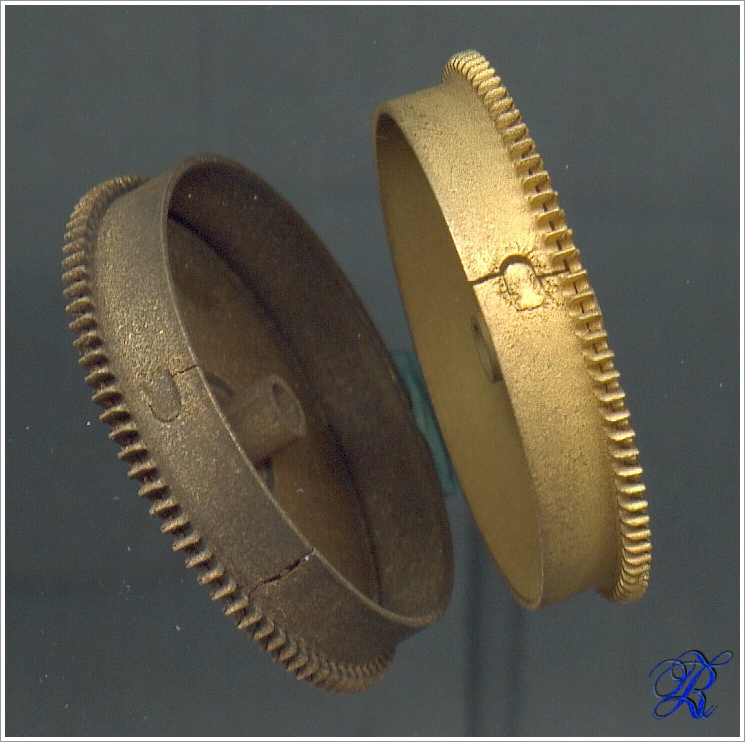

It is an impressive quantity of washes but it is only from a couple of years that the two barrels began to crack, after about 500 cleanings, ultrasonic treatments and rinsing. Fissures are located where the material is more stressed, near the hook and at the root of teeth. One barrel wheel started to detach from the barrel wall.

Cracked barrel hook with detached wheel

One barrel (left) is cracked on the wall, too

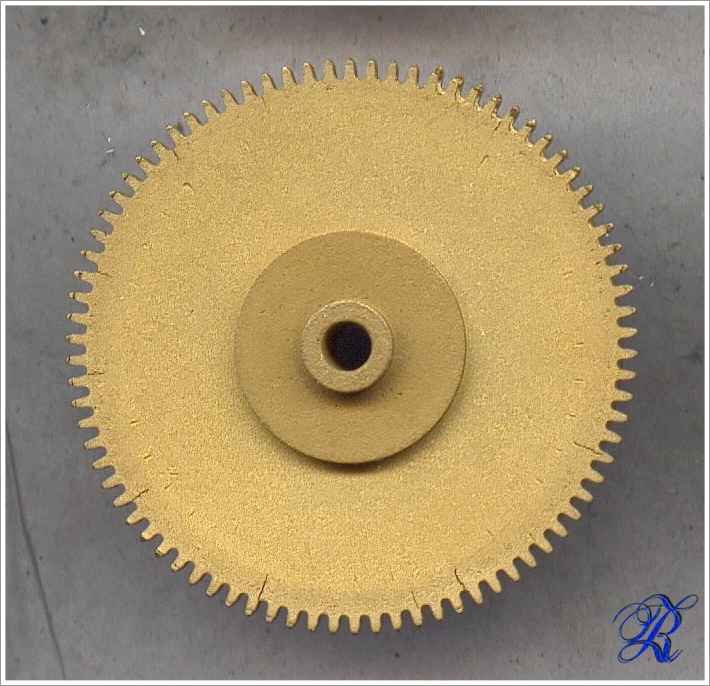

Tiny cracks are visible at the base of wheel teeth

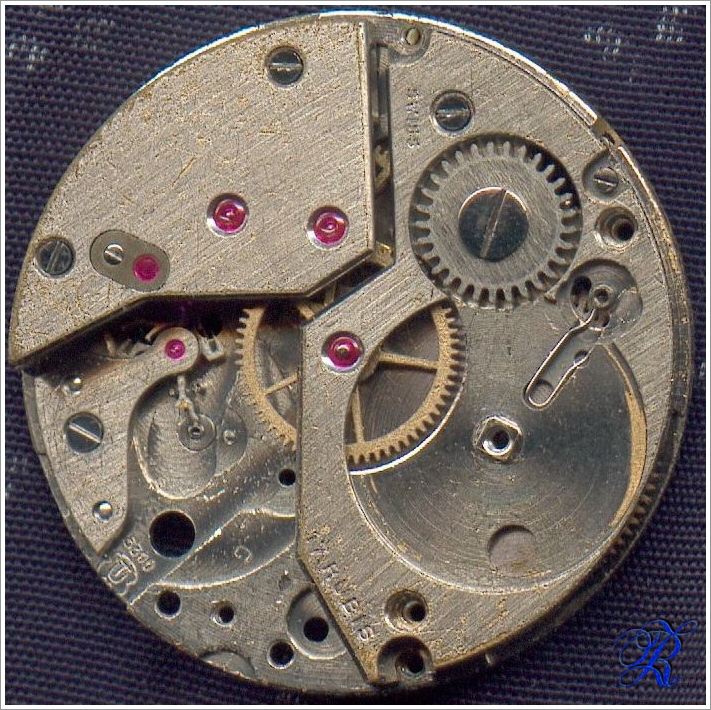

Watch movements show no sign of damage on plates; brass wheels, not gilded, appear to be quite porous, like alarm clock barrels, but not cracked (possibly because wire erosion did not stress brass as traditional cutters did with alarm clock barrels, but this point should be further investigated).

Vintage wristwatch movement lost part of nickel plating. Brass wheels became porous but did not crack

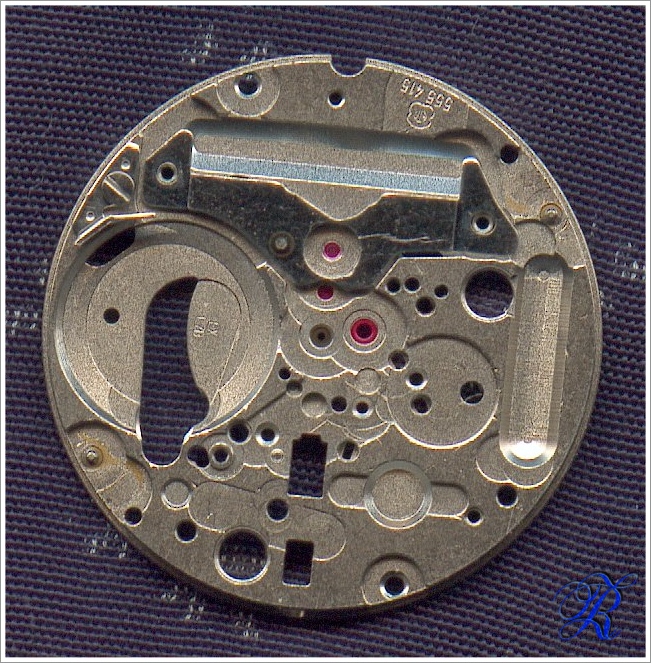

Surface treatments (nickel plating and gilding) protect brass very well. Nickel plating is more durable in modern movements than in vintage ones.

Modern wristwatch movement shows no problems at all. Nickel plating is still very good. Gilded wheels are intact

Quartz movement plate is the best preserved part. Nickel plating is absolutely as new.

Modern nickel plating also appears to be a little more durable than modern gold plating, at least in our samples.

This is not a true “experiment”: we did not examine a very large number of items, only a few from our own experience, so conclusions should be taken into account very carefully.

Nonetheless it appears safe to affirm that nickel plated or gilded modern movements can be washed with ammoniated solutions and treated with ultrasonic machines for a vast number of times without any risk.

This is a test that no other clock or watch all over the world will luckily have to face. Theoretically, a fraction of the damage shown by our barrels is caused to every clock washed in ammoniated fluids, but we believe it is so small it can really be neglected.

An antique clock will terminate its life much sooner than having to stand 500 cleanings, 500 ultrasonic treatments and 1,500 rinsings (each of them 8 minutes long) as our barrels did before cracking. Supposing an overhaul is performed every four years, with a four minutes bath in ammonia solution (exactly ¼ of the time our barrels had to “suffer” during their washes) a clock would show cracks on brass parts after 500*4*4=8,000 years! This gives ample safety margin for errors in calculations. Even if our estimate, made on a small number of items, would be quite wrong, things would not change that much.

It appears that the time spent on the crusade against ammoniated fluids (including this brief description of our experience) should actually be devoted to more compelling problems. For example: how many watch or clockmakers throw away their cleaning fluids and lubricants at regular time intervals? It is a very good practice, avoiding many more problems than those caused by ammoniated fluids alone.

This immediately brings to mind another topic that is very often debated by the watchmakers’ community: is it better to clean watch movements completely or only partly disassembled? Many people answer that they are best cleaned when washed fully dismantled. This is common believe, but even “The Swiss Watch Repairer’s Manual” by H. Jendritzki, a reference book for Swiss service centers, says it is not necessary to completely disassemble movements with the sole purpose of better cleaning them. Again, this is not the point: watch movements are satisfyingly cleaned both fully or partly disassembled, given that the cleaning solution is in pristine conditions. This means not to wait for washed movements to appear dirt before changing it!

We believe that the ammoniated cleaning solutions issue is so debated because even the “worst” practice is not so bad, and this allows for a never-ending discussion. Many respected repairers and restorers have used this method for decades. Leaving parts in ammonia based solutions for no more than a few minutes causes very little if no damage at all. The time we are spending investigating this problem would be much better used in improving our general techniques and skills, which could more substantially extend a clock’s life. But may be these are not so easily debatable and surely are not so a pleasure to discuss with friends.