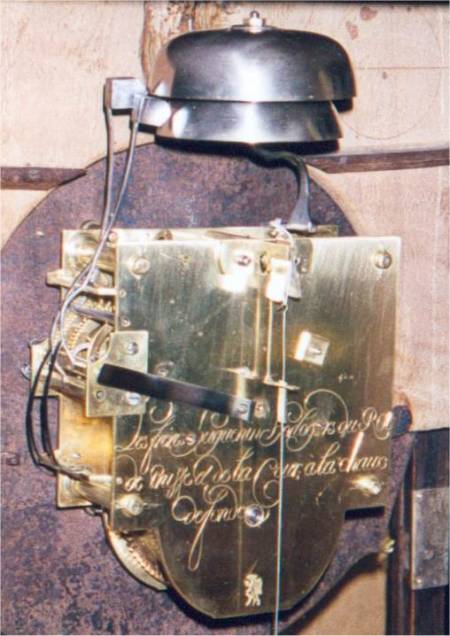

The clock was made in La Chaux-de-Fonds, Switzerland, as it is engraved on the back plate.

The quarter chime uses one train of wheels only, which shares the motive power with the time train. There is only one barrel.

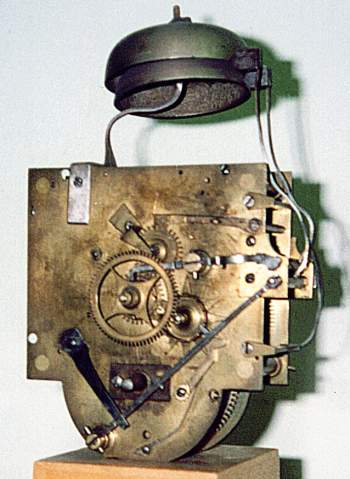

The original barrel assembly was badly damaged as it can be seen from these pictures:

It could not be repaired so it was necessary to reconstruct it, since the owner wanted a running clock, not only a pretty preserved one.

All this was mainly due to some project errors: the mainspring was too strong if compared with the remainder of the barrel assembly which had to contain it. Many signs of past repairs are visible, especially to the clicks and their fixing points on main wheels which have a lot of abandoned holes.

The new parts had to be designed to be much more reliable than old ones!

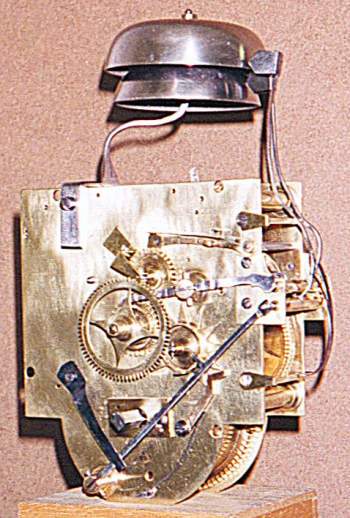

Here they are ready for testing, before final polishing:

The space available for the mainspring inside the barrel was reduced to increase the thickness of main wheels and of the click and ratchet assembly, which are now much more robust than in the past. It was decided to use one click only instead of the two that were used in the original barrel, to employ a bigger and more reliable click spring. The ratchet wheel is no more fixed to the barrel arbor with a pin but is coupled on a large milled square. Finally, the clock had in origin a Maltese Cross stopwork which was not reproduced to avoid decreasing main wheels thickness, which was critical for the reliability of the whole barrel assembly.

The finished movement:

The clock completed:

This screw shows how differently these clocks were made if confronted with those manufactured during the Industrial Revolution. One does not have to be a clockmaker to understand that this part was almost entirely handmade!